The fish tanks/ basins made from HDPE or PP standard equipped with:

Water outflow connection with grid

Water level stand-pipe

Emergency oxygen diffuser

Level sensor

SYSTEM COMPONENTS/ EQUIPMENT

Fish Tanks

Water treatment

Removal of solids from faeces and uneaten feed (SS removal)

Decomposition of dissolved organic solids (BOD/COD removal)

Conversion of (toxic) ammonium into nitrite (nitrification)

Conversion of nitrite to nitrate and further to N2 gas (denitrification)

Phosphorus removal (de-phosphate)

Removal of carbon dioxide (Co2)

Mechanical filtration

Water returning from the fish tanks enters the first phase

of the treatment unit, the self-cleaning mechanical filter.

Here water passes through a fine mesh, a micro screen.

The solids (mainly fish faeces) flows as effluent to the waste water treatment.

Moving bed; biological filtration

Moving bed biological filter consist of a sump filled with a biofilter material (small plastic particles).

The water is continuously aerated, causing the biofilter movement.

Result, removal of Ammonia, dissolve organic material and stripping the carbon dioxide.

Trickling, fixed bed filtration

Closed tower filled with bio media and water dispensing system.

Bacteria break down waste products.

Aeration is used to add oxygen and strip carbon dioxide.

Result, Add oxygen, removal of Ammonia,

dissolve organic material and stripping the carbon dioxide.

Protein Skimmer

The protein skimmer is used to remove fine solids and protein.

In the reactor in where foam is created by aerating the water

with a centrifugal pump driven venturi

Ultra violet filter

The UV technology method is based on the natural disinfectant action of the sun’s rays.

UV lamps imitate the disinfecting rays of the sun.

The UV systems produce the same ultraviolet germicidal rays,

just thousands of times stronger. No bacteria, viruses can withstand this treatment.

The reaction time between the UV irradiation and the organism to be killed

is very short and does not create any by-products at all.

Oxygen Reactor

Water that has passed the treatment unit is ready for re-introduction to the fish tanks.

For intensive fish farming, super saturated water is required.

This filtered water is pumped through a ‘reactor’, a high-pressure vessel,

in here water becomes supersaturated with oxygen.

Achieved by a combination of gas exchange and by static pressure on the water.

The quantity of oxygen is automatically dosed.

Oxygen control panels

The dissolved oxygen (DO) is measured in oxygen control unit.

Pure oxygen from an oxygen generator or from a liquid oxygen source,

directed to an oxygen reactor via the oxygen control panel.

In case of power failure automatically an emergency diffuser system opens

The Oxygen is delivered on the demand, avoiding unnecessary oxygen loss.

Pumps

In order to transport water from filter to fish tanks, centrifugal pumps are used. All pumps are upgraded to the required conditions like temperature and salinity level of the system water

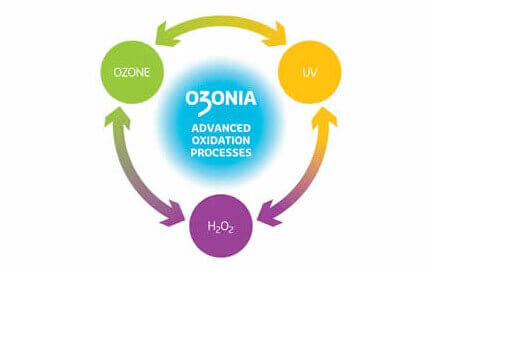

Ozone generator

Ozone can play important roles in the prevention and elimination of fish diseases in aquaculture systems.

This powerful oxidizing agent disinfects and oxidizes organic pollutants while increasing the water's dissolved oxygen level.

The end result is exceptional water quality, which is a fundamental requirement for intensive fish farming.

Cooling and heating system

Fish species live under different conditions such as temperature.

Automatic regulation and control of the system water is required.

the system is supplied as complete turn key solution.

Diesel generator

In case of energy failure, the stand-by diesel generator takes over automatically.

Complete installed including net overtake.

PLC automation

All electrical items and sensors are controlled in the switchboards.

complete installed incl. main electricity board, current control and back up board.

Pipe connection network

Complete installation of the pipe network.

• Outflow and inflow between tanks and filter

• Effluent from filters to waste water treatment

• Oxygen

• Electricity

• Heating and Cooling

Waste water treatment

All effluent from the filters are collected and treated by the waste water treatment before discharge to municipal system, pond, channel or river. The waste water unit is a combination of de-nitrification filter and de-phosphating filter. impressive results are achieved. Test results are available of several years of on-site tests in real-life conditions at different fish farms and conditions.

Control system

The control unit, measures and control the parameters plus pressure and water levels

PSA oxygen generator

Pure oxygen is essential in all indoor fish farms.

Oxygen generator is the alternative for liquid oxygen supply.

Average performance/consumption is 1KW/kg o2

Feeders

Automatic feeding by computer program, stationary feeders or Robot. The stationary feeders are available with 1,6,9 and 50 ltr hoppers. Feeding size 0.3-8mm. The dosing from 0.1 till 100 gr.